- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

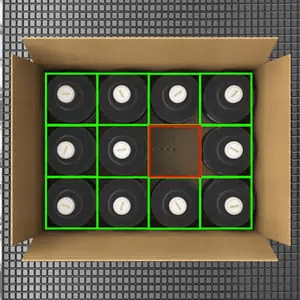

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Digital Concepts & VR Walkthroughs are Revolutionizing Factory Design with Automate and Control LTD

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Orders

- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Digital Concepts & VR Walkthroughs are Revolutionizing Factory Design with Automate and Control LTD

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Orders

What is Machine Vision?

Machine vision refers to the use of image capture and processing technologies to automate visual inspection and analysis tasks. It involves the use of cameras, lighting, and software algorithms to acquire and interpret visual data. In the automotive industry, machine vision systems are employed to inspect parts, verify assembly, and guide robotic operations, ensuring high standards of quality and efficiency.

The Role of Automated Inspection Systems

Automated inspection systems leverage advanced imaging technology to evaluate products in real-time. Unlike manual inspection, which can be time-consuming and prone to human error, automated systems provide consistent, accurate, and rapid assessments. Key components of these systems include high-resolution cameras, lighting, and sophisticated software algorithms that analyze visual data to detect defects and deviations from set standards.

Vision

SYSTEMS

Applications of Machine Vision in the Automotive Industry

Inspection and Quality Control

- Surface Defect Detection: Machine vision systems detect surface defects such as scratches, dents, and paint flaws on automotive components. High-resolution cameras capture detailed images, while AI algorithms analyze these images to identify imperfections that may not be visible to the human eye.

- Dimensional Measurement: Ensuring that parts meet precise specifications is critical in automotive manufacturing. Machine vision systems measure dimensions with high accuracy, identifying any deviations from the required tolerances.

Assembly Verification

- Component Presence and Placement: Machine vision verifies the presence and correct placement of components during assembly. This ensures that all parts are correctly assembled, reducing the risk of defects and enhancing overall product quality.

- Weld Inspection: In automotive welding processes, machine vision systems inspect weld quality, detecting defects such as incomplete welds or excessive spatter, which could compromise structural integrity.

Robotic Guidance

- Precision Guidance: Machine vision guides robotic arms with precision, enabling accurate positioning and manipulation of components. This is particularly important in tasks such as painting, sealing, and assembly, where precision is critical.

- Adaptive Manufacturing: Machine vision systems can adapt to variations in parts and assembly conditions, providing real-time feedback to robots and ensuring consistent performance.

Safety and Compliance

- Safety Inspection: Machine vision systems inspect safety-critical components, such as airbags and seatbelts, ensuring they meet stringent safety standards.

- Regulatory Compliance: These systems help manufacturers comply with industry regulations by ensuring that all components meet required specifications and quality standards.

Benefits of Machine Vision in Automotive Manufacturing

The integration of machine vision technology offers numerous benefits to the automotive industry:

- Enhanced Quality: Machine vision systems provide consistent, accurate inspections, ensuring that only high-quality products reach the market.

- Increased Efficiency: Automated inspections reduce the need for manual checks, speeding up production lines and increasing throughput.

- Cost Savings: By detecting defects early, machine vision systems minimize waste and reduce the cost of rework and recalls.

- Improved Safety: Ensuring the quality of safety-critical components enhances vehicle safety, protecting consumers and reducing liability for manufacturers.

- Data-Driven Insights: Machine vision systems generate valuable data that can be analyzed to identify trends, optimize processes, and predict maintenance needs.

Case Studies

- Tesla’s Gigafactory: Tesla has implemented machine vision technology extensively in its Gigafactory, using it for tasks ranging from inspecting battery cells to guiding robotic arms. This has resulted in improved production efficiency and reduced defect rates.

- BMW’s Smart Factory: BMW’s smart factories utilize machine vision for quality control and assembly verification. The integration of AI-driven machine vision systems has enhanced BMW’s ability to maintain high standards of quality while increasing production speed.

Future Trends

The future of machine vision in the automotive industry is promising, with several trends set to drive further advancements:

- AI and Deep Learning: The integration of AI and deep learning algorithms will enhance the capability of machine vision systems to learn and adapt, improving accuracy and reducing false positives.

- 3D Vision Systems: The development of 3D vision systems will enable more detailed inspections and measurements, providing a more comprehensive understanding of complex parts and assemblies.

- Edge Computing: Edge computing will allow machine vision systems to process data locally, reducing latency and enabling real-time decision-making on the production line.

Conclusion

Machine vision technology is revolutionizing automotive production lines, providing manufacturers with the tools to enhance quality, efficiency, and safety. By leveraging advanced imaging systems and AI, machine vision enables precise inspection, measurement, and guidance, transforming traditional manufacturing processes. As technology continues to evolve, the capabilities of machine vision systems will only expand, driving further innovation in the automotive industry.